WIWOX® ED Stainless steel

metallic − round

Product description

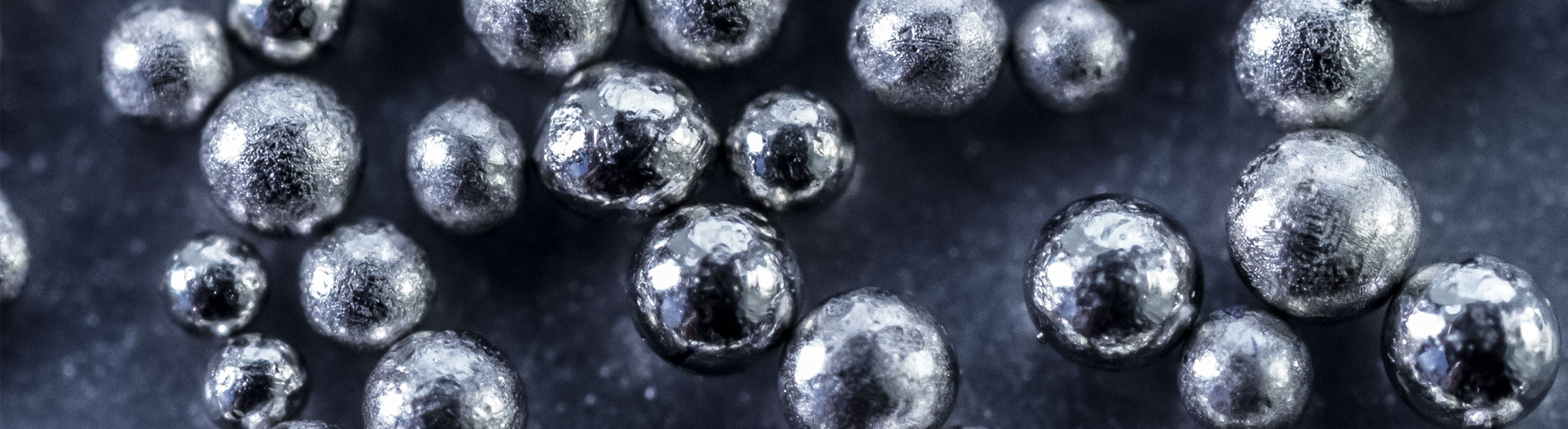

WIWOX® ED Stainless steel blasting abrasives are produced in a melting process and get its round shape through the subsequent atomising process. These fine particles have a particularly long service life and are known for low dust generation. We also supply stainless steel blasting abrasives manufactured under vacuum that meet the requirement of particularly high demands.

This blasting abrasive is distinguished by its lustre, purity and roundness.

Suitable blasting processes

- Pressure blasting process

- Blast wheel blasting process

Applications

- Sand removal

- Descaling

- Micro / structural blasting

- Reusable abrasive

Technical data

Color

Grain shape

Hardness

Melting point

Bulk weight

Specific weight

Cr (Chrome)

Ni (Nickel)

Si (Silicon)

Mn (Manganese)

C (Carbon)

Silver

Round

+/- 20 HRC (235 HV)

approx. 1.450 – 1.500° C

approx. 3,8 – 4,6 g/cm³

approx. 7,9 g/cm³

16 – 20 %

7 – 9 %

1,8 – 2,2 %

0,70 – 1,20 %

0,05 – 0,20 %

| Product name | Grain field | Delivery unit |

|---|---|---|

| WIWOX® ED 010 | 100 – 200 μm | 25 kg Sack / 1000 kg BigBag |

| WIWOX® ED 020 | 150 – 300 μm | 25 kg Sack / 1000 kg BigBag |

| WIWOX® ED 030 | 140 – 500 μm | 25 kg Sack / 1000 kg BigBag |

| WIWOX® ED 040 | 300 – 600 μm | 25 kg Sack / 1000 kg BigBag |

| WIWOX® ED 060 | 700 – 1.250 μm | 25 kg Sack / 1000 kg BigBag |

In addition to the listed blasting media, we also stock other types and grain sizes as well as our own special blasting media.